Computer-aided Inspection of Surgical Implants

Surgical Implants are typically organically shaped and very difficult to inspect. Absolute Geometries can solve that problem by using 3D scanning to perform 100% inspection of the implant. Where normally a few reference points would be checked, 3D scanning enables the entire surface to be inspected.

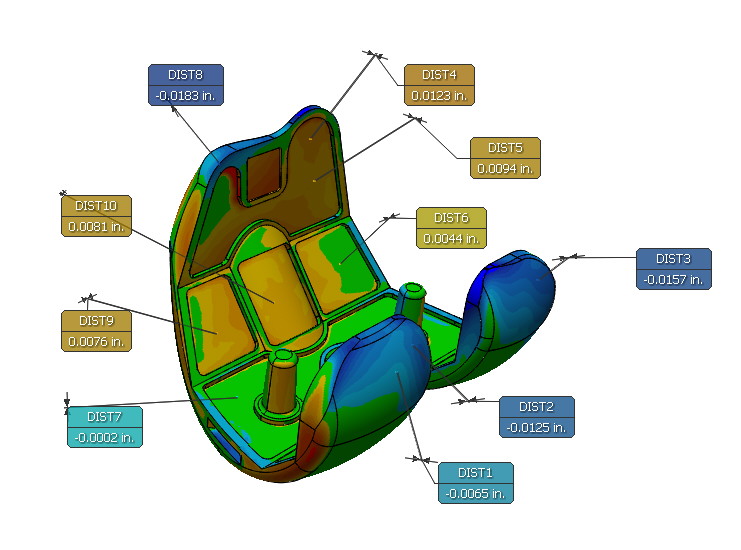

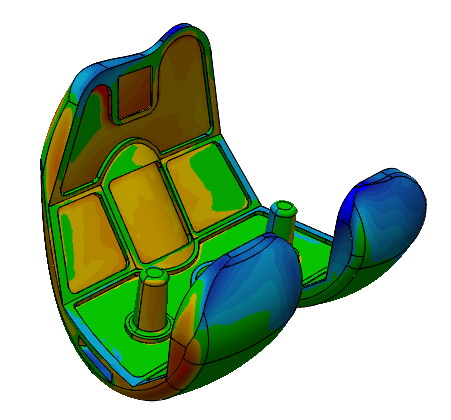

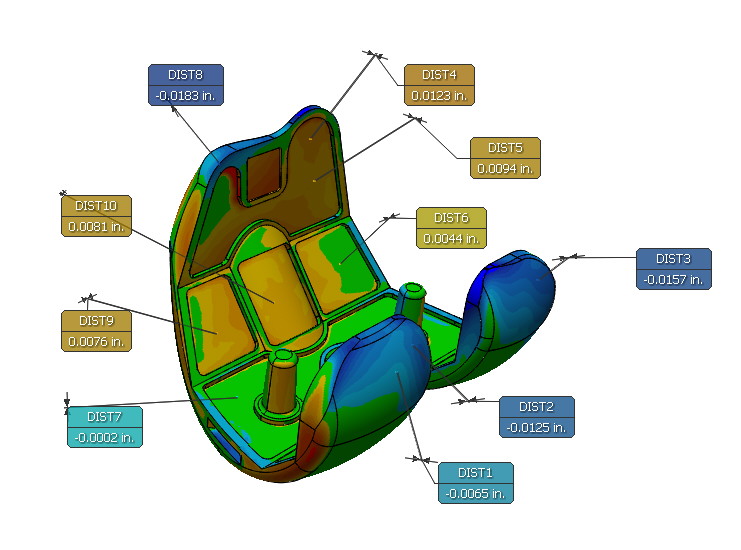

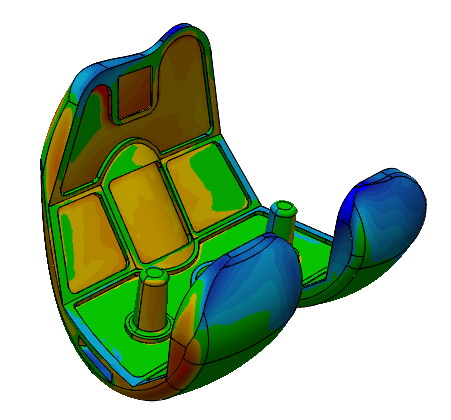

The process involves scanning the implant, and then aligning the scan data with the original CAD file. Once that is complete, a 3D color deviation map can be created. The deviation map shows in color where the scan data is different from the CAD data and by how much. A tolerance is defined and any points that are within that tolerance will show as green. Points that are above the CAD data will show as yellow to red and points that are below will show up as blue.

Reference dimensions can be take at any point on the model or an array of dimension points can be defined. The array can be helpful when multiple parts are being inspected and it is important to inspect the exact same point on each part.

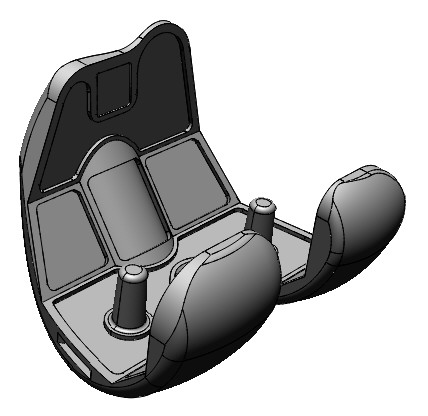

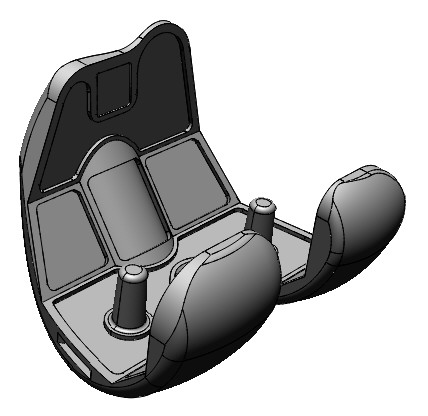

Original CAD data

Original CAD data

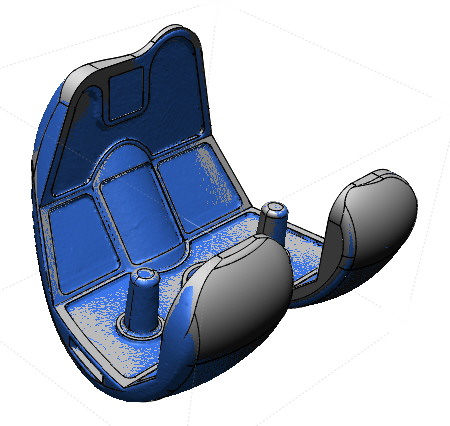

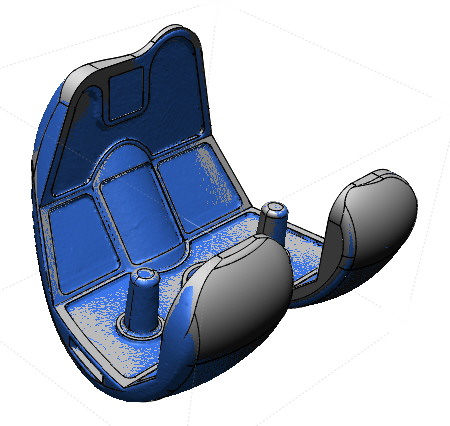

Scan data

Scan data

Scan data is aligned to CAD data

Scan data is aligned to CAD data

Color Deviation Map is created

Color Deviation Map is created

After the scan data has been aligned to the CAD data, a 3D color deviation model is created that will show where and how much the data differs.

Original CAD data

Original CAD data Scan data

Scan data Scan data is aligned to CAD data

Scan data is aligned to CAD data Color Deviation Map is created

Color Deviation Map is created